About Us

Where we Are

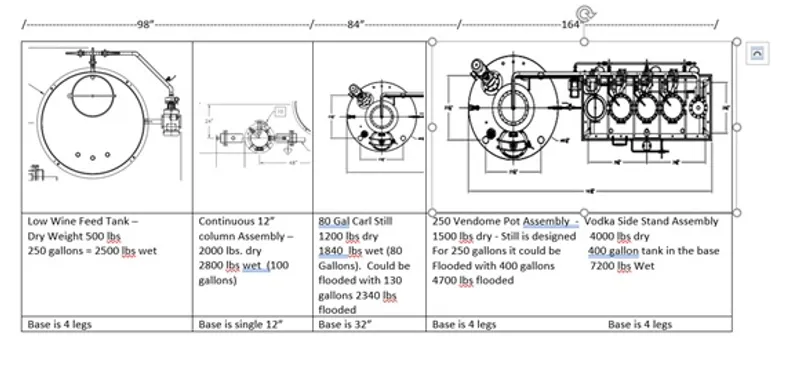

As the first Farmer Distiller in Massachusetts, Nashoba has been operating as a premiere boutique distiller since beginning of the century. Crafting our skills and learning our trade, we the start of the second generation of farmers comes a new focus on growth and quality. With our 80 gallon still in hand, let us introduce you to the future.

The Search

While distilling is an art, the art can be lost without the right partner. Planning for the future started with finding the right partner and we wanted to partner with an American company so where else to look but Kentucky.

Since the turn of the century, Vendome has been a major provider of distillation systems for Distillers world-wide. Custom hand crafted equipment specific to making fine bourbon, rum, gin, vodka and other spirits. After discussion with Kyle of Vendome and seeking advice from over 50 distillers throughout the United States it was an easy decision to put our trust in Vendome for the custom design and engineering of each piece of equipment we wanted to incorporate into our system.

In addition to the stills, we fabricate all related stainless steel and copper equipment including fermenters, cookers, condensers, coolers, whiskey tanks, bottling tanks, etc.

The Plans

The Continuous Copper Condenser/Beer Heater

The above picture is not quite how our still is column is arranged but works exactly the same way. The tank on the far right is the doubler or our 80 gallon still. The continuous column still is filled with perforated plates. The beer to be distilled is pumped in near the top of the column (but not at the very top), and steam is pumped up from the bottom of the column. While the plates are perforated, this lets the steam come up through the still, but the beer does not drip down through the perforations. Rather, the beer runs across each plate to the other side, flows down to the next plate and flow across it to the other side.

The steam coming up through the column vaporizes the alcohol from the beer (which then flows to the top of the column), while leaving the water and grain solids to keep dripping down to the bottom. (As in every still, it is tuned so that the alcohol that has a lower boiling temperature evaporates off, leaving the water with its lower boiling point behind.)

The beer enters the still around the 5th plate as the top four plates are purely rectification plates for the alcohol produced. It is up there where copper is crucial, and where you find “bubble caps” in stills. Above the plates is a beer heater at the top which acts kind of like a dephlegmator. The beer/wine being pumped from a tank gets heated by the vapors and partially cools the vapors. The vapors that makes it through the beer heater goes on to the condenser. Anything that collapses re-enters the column as reflux and is redistilled. The slop is removed at a constant rate from the bottom.

The distillate continues to where it gets distilled again in a doubler or thumper. Distillate is produced consistently with exceptional quality with no need to make heads, hearts, and tails cuts. 750 gallons and up are the best size for batches. It is mainly for mid-proof products and is excellent for bourbon, whiskey, and rum. There are several advantages to using a continuous system. Products that go into the barrel to age is where continuous distillation really excels, because of its ability to distill products with great consistency 24/7 without shutting down. Faster more efficient production requires less labor. Also is great for stripping low wines paired with a batch still to make vodka and gin as well. The disadvantages are that it requires 30′ of ceiling height, it is not well suited for small batches, it is more difficult to run when first starting up, and requires more skill and knowledge.

Most column stills can be built from stainless steel but there needs to be interaction with copper at some point. The part of the still where beer is being separated and distilled is stainless, and where the steam is being rectified is copper.

Bubble caps provide additional refinement of the spirit and increase contact with copper. Some other stills are filled at the top with bits of shredded copper or copper pieces that look like jacks for similar reasons.

This also makes it easier to replace the copper at the top of the still or inside the top when needed, rather than the whole still column that can last for decades.

At low proof copper contact is essential for removing sulfides from the alcohol. The only reason that the condenser and beer heater don’t come standard as copper is because most people getting the continuous stripping column are doing a second distillation in an all copper, or mostly copper, vessel. The higher the proof you distill to, the less copper you actually need in the system to remove the sulfides, which is why some vodka systems have absolutely no copper in them.

The copper rectification section adds additional copper contact and, of course, additional rectification. It gives you a little more control over the proof coming off the still along with increasing maximum proof. The continuous still that we purchased needs a consistent 540-600 lbs. of steam/hour to the column. -There are [automated] controls for the beer/wine feed pump and the bottoms pump. All three pumps, however, include VFDs (variable frequency drives (expensive) ) to better control them. -(3) pumps are included… beer feed pump (mash going into the column), bottoms pump (spent mash exiting the column), and an alcohol pump for transferring low wines out of the low wine tank to another vessel or to the pot still for second distillation are included. The alcohol pump could also be used to pump to a doubler, which is what our existing pot still will become.

The beer in the above diagram goes into the still at Plate 15, the new-make spirit is condensed and sent to the pot still (doubler), then recondensed before entering the High Wine Tank at the end. Optimal feed rate for the column is 3.5-4 GPM or 210 gallons per hour or 1260 gallons in a 6 hour run. ABV will determine what feed rate the column operates best at. Spent mash out will be very close to the same GPM as the mash feeding in depending on your ABV of the product going in and what proof the column is producing. The product out of the column still is called low wines and will likely be between 100 and 130 proof. Assuming 5% alcohol apple mash going into the still, production output will be about 16.66 gallons per hour or about 100 gallons per day (6 hour day and 80% efficiency.

1260 gallons at 5% will yield approximately 63 gallons at 100% or 126 gallons at 50% (1260X.05)

The second distillation in the doubler will be running simultaneously receiving the low wines and producing finished product in the 76% range for a total yield of 82 gallons. At 90% efficiency this would be 74 gallons and at 80% efficiency it would be 66 gallons or 27 ½ cases of spirits per day or 560 cases per month. Running 24 hours per day – 2240 cases per month!!!!!!!!!!!

The Doubler or Thumper in Bourbon Distillation

Most bourbon undergoes a second distillation in a continuous pot still called a doubler of a thumper. Sometimes it looks just like a regular pot still. In other distilleries, it looks just like a flat-topped metal container- you wouldn’t know it’s doing anything.

In a doubler, the vapor off the column still is condensed back into liquid and this is run through the pot still. In a thumper, the vapor itself goes into the still to be redistilled (and makes a thumping sound that I’ve never heard but I associate with the sound of radiator pipes clanging in East Coast apartment buildings).

This second distillation is needed to raise the proof of the distilled spirit a little further, and this can be done in a pot still because there are no longer any solids to worry about. The waste product of the doubler/thumper is additional water.

The slop is removed at a constant rate from the bottom. The distillate continues to where it gets distilled again in a doubler or thumper.

250 Pot still.

250 gallon Pot Still with Vodka Column

80 Gallon Pot Still

Barrel Strength 125 Proof/62.5% A.B.V. 3-4 Hour Run Time

17 Gallons

7 gallons

Bottle Strength 80 Proof/40% A.B.V. 3-4 Hour Run Time

26 Gallons

80 gallons

NGS 190 Proof/95% A.B.V. 7-10 Hour Run Time

Not Possible

The Results

When Completed, the addition of a continuous column still, the use of our current still as a doubler, the addition of a second 250 gallon Pot still and a vodka column, we possess the tools to transform Nashoba from a great winery to a great winery and incredible distillery. Nothing in New England will compare once our expansion is complete.